The quality and authenticity of every component that leaves our warehouse is our #1 priority.

We offer a variety of In-House and Value Add Services to ensure authenticity and satisfaction.

Our extremely thorough incoming and outgoing inspection processes are tailored to customer requirements.

We are always looking for self-motivated and hard working individuals to join our dedicated staff.

About Us

As an international integrated supplier of sensors, measuring systems, laser printers, microscopy systems and stand-alone imaging systems, we continue to drive innovation and development in factory automation. We are committed to developing high-quality and reliable products to meet the needs of customers in all kinds of manufacturing industries.

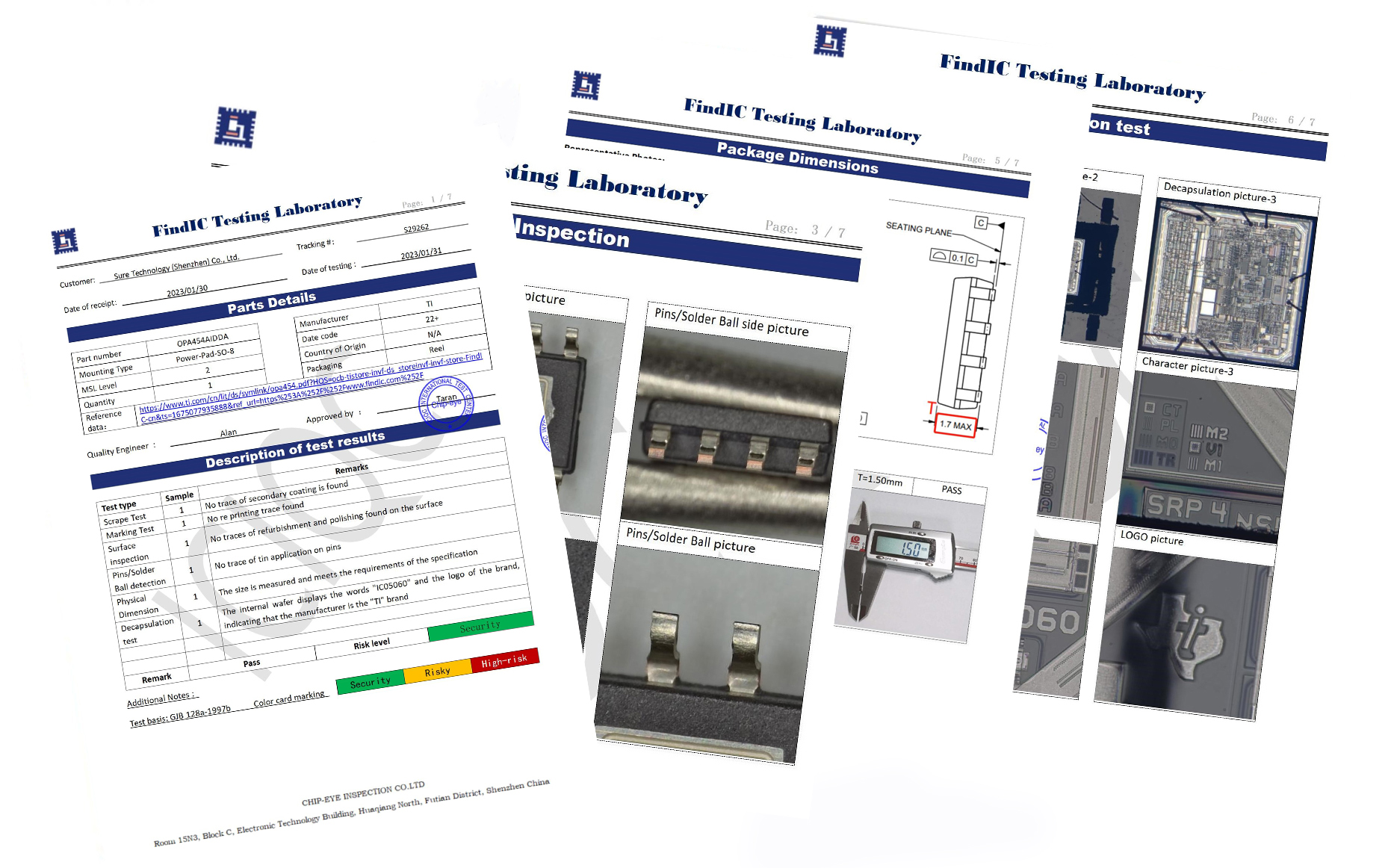

Quality Control is the prime focus at Sure Technology. Our Quality Management System provides the framework for consistent and reliable transactions. Our inspection process includes a rigorous counterfeit detection process. Inspection personnel are continually trained in the latest detection methods. Most often, we can supply products with full manufacturer's traceability, airworthiness, or test certifications.

Quality

Assurance

The purpose of Sure Technology is to build a customer base of satisfied customers by delivering stent timely shipments of authentic, high-quality products that meet their requirements and which are processed by a unified team of knowledgeable and inspired people. The processes and resources used to supply these products shall be organized, monitored, measured, and continually improved upon in a manner that reduces risks, costs, and inefficiencies.

Inspection Process

Our incoming and outgoing inspection processes are tailored to customer requirements using flow downs and unique process set-ups. Our inspectors are well trained with years of hands-on experience.

OUR COMPANY'S CORE:

Assurance

Quality

Quality Policy

The purpose of Sure Technology is to build a customer base of satisfied customers by delivering consistent timely shipments of authentic, high-quality products that meet their requirements and which are processed by a unified team of knowledgeable and inspired people. The processes and resources used to supply these products shall be organized, monitored, measured, and continually improved upon in a manner that reduces risks, costs, and inefficiencies.

Inspection Process

Our incoming and outgoing inspection processes are tailored to customer requirements using flow downs and unique process set-ups. Counterfeit detection is utilized in all inspections. Our inspectors are well trained with years of hands-on experience.

Traceability

We are a hybrid distributor of products where traceability requirements are dependent on customer needs. Products coming from one of our many franchise lines have full manufacturer trace and warranty. Other items will have trace levels that are agreed upon with our customers at time of quotation.

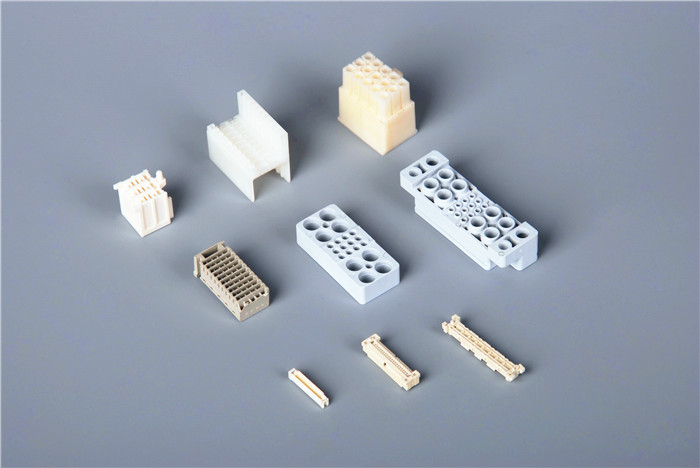

Our

Products

◎ Sensors

◎ Measurement Sensors

◎ Measurement Systems Safety

◎ Process Controls

◎ Process Sensors

◎ Static Eliminators

◎ Ionisers Vision

◎ Controls

◎ Laser Makers

◎ Barcode Readers

Our

Services

◎ Shortage Solution

◎ Cost Down

◎ NPI & Free Sample

◎ Excess Management

◎ BOM & Market Analysis

◎ Flexible Payment Term

Our In-House

Inspection Process

Our experienced and knowledgeable inspection staff performs detailed inspections on all incoming and outgoing product. Inspection criteria for a wide range of product types are pre-established and based upon the IDEA STD 1010, AS6081, CCAP101, and AS5553 standards.

X-Ray

Inspection

AS6081 inspections include x-ray inspections to ensure lots have consistent internal construction.

X-Ray

Inspection

AS6081 inspections include x-ray inspections to ensure lots have consistent internal construction.

Our two standard levels of inspections provide customers a choice of inspection to fit their needs. Customers can also design their own Custom Inspection Plan to meet specific order requirements.

X-Ray

Inspection

AS6081 inspections include x-ray inspections to ensure lots have consistent internal construction.

X-Ray

Inspection

AS6081 inspections include x-ray inspections to ensure lots have consistent internal construction.

Standard Inspections:

Our two standard levels of inspections provide customers a choice of inspection to fit their needs. Customers can also design their own Custom Inspection Plan to meet specific order requirements.

Inspection based on IDEA STD 1010

- Documentation

- Packaging

- Part Package Type

- Lead/Ball Condition

- Part Marking

- Surface Testing

- Rohs Status

- ERAI Review

AS6081 Based Inspection w/ Report

- X-Ray

- XRF

- Solderability

- Heated Solvent Testing

- Die Verification

- Scanning Electron Microscopy (SEM) When Required

Tailored Inspection

- Inspection plans can be customized to meet customer requirements.

CAREERS

Let's grow

together

TESTIMONIALS

Some words

from our clients

“KEEP UP THE

"GREAT" WORK!!!!!! I started using

Abstract at the beginning of 2018.

To date, there have been no issues.

Price is always competitive, the

customer service rep is very

knowledgeable, and their quality

inspection staff is a good as it

gets.” — Buyer,OEM

“KEEP UP THE

"GREAT" WORK!!!!!! I started using

Abstract at the beginning of 2018.

To date, there have been no issues.

Price is always competitive, the

customer service rep is very

knowledgeable, and their quality

inspection staff is a good as it

gets.” — Buyer,OEM